eVision

The components guarantee precision cutting

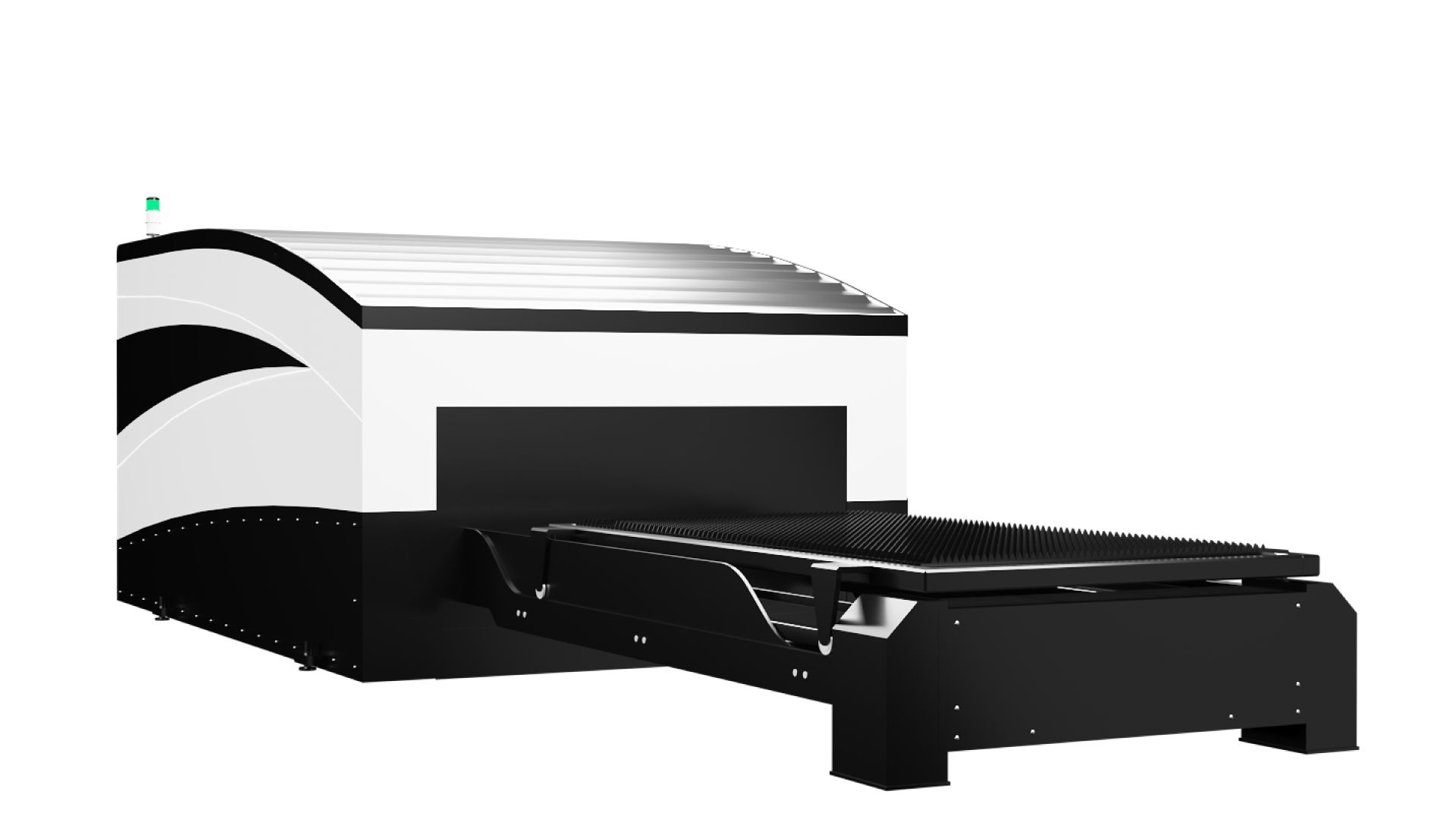

The eVision laser cutting machines are universal and provide the best results for any production. Whether you run large or small batches, cut thin or thick sheets, this series will deliver optimum results 24/7.

With a top cutting speed of 150m/min, positioning speed of 180m/min, acceleration up to 3G, and fiber laser powers from 1 to 30kW, the eVision systems are ready to take your shop’s production to the next level.

Standard Equipment

- Fiber laser source

- Linear motors on all axes

- Advanced composite material body structure

- Rigid steel traverse bridge

- eVa cutting head

- Superfast pallet changer without hydraulics

For demanding mass production.

The eVision series of laser cutting machines is characterized by high dynamics and top quality. The machines achieve a positioning speed of up to 180m/min and acceleration of 3G. They are characterized by the highest cut part precision and failure-free operation. Each laser cutter is available with a fiber laser source with power ranging from 1 to 30 kW. Thanks to their compact design, laser metal cutting machines take up the least amount of room of the machines available on the market, and easy-to-use software makes it possible to start work immediately.

Benefits

- Made for 24/7 automation

- Flexible range of material thicknesses

- Best efficiency and precision

- Intelligent design to minimize the footprint on the floor space

- Lowest maintenance on the market

- Reduced energy consumption

- Intelligent construction made to last

- Lowest cost per part

- Best throughput quality

- Best performances and reliability on the market

Technical data

Work area

| MACHINE MODEL | [jm] | 1530 | 2040 | 2060 | 2560 | 2580 | 3080 | 25120 | 25160 | 30120 | 30160 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| X-axis | [mm] | 3060 | 4060 | 6060 | 6060 | 8070 | 8070 | 12090 | 16110 | 12090 | 16110 |

| Y-axis | [mm] | 1540 | 2040 | 2040 | 2540 | 2598 | 3098 | 2598 | 2598 | 3098 | 3098 |

| Z-axis | [mm] | 100 | 100 | 100 | 100 | 150 | 150 | 150 | 150 | 150 | 150 |

| Max. weight of the sheet | [kg] | 1000 | 1600 | 2400 | 3000 | 9600 | 11520 | 14400 | 19200 | 17280 | 23040 |

Dimensions and weight of the machine 1)

| MACHINE MODEL | [jm] | 1530 | 2040 | 2060 | 2560 | 2580 | 3080 | 25120 | 30120 | 25160 | 30160 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length | [mm] | 10000 | 11200 | 14000 | 14000 | 22550 | 22550 | 31330 | 31330 | 41000 | 42000 |

| Width | [mm] | 3080 | 4100 | 4100 | 4750 | 4500 | 5000 | 4500 | 5770 | 4600 | 5900 |

| Height | [mm] | 3060 | 3060 | 3060 | 3060 | 2700 | 2700 | 2750 | 2850 | 2800 | 2900 |

| Weight | [t] | 18 | 22 | 36 | 39 | 66 | 72 | 144 | 177 | 287 | 395 |

1) Approximate values. The exact parameters are specified in the machine’s installation plan.

| MAXIMUM SPEEDS | ||

|---|---|---|

| Parallel to the X, Y and Z axes | 180 | [m/min] |

| Simultaneous | 180 | [m/min] |

| AXIS PARAMETERS | ||

|---|---|---|

| Repetitiveness | 0,03 | [mm] |

| Precision | 0,1 | [mm] |

| Acceleration | 30 | [m/s2] |

| Min. programmable step | 0,001 | [mm] |

| AVAILABLE LASER SOURCE | [jm] | 1kW | 2kW | 3kW | 4kW | 6kW | 8kW | 10kW | 12kW | 15kW | 20kW |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mild steel | [mm] | 10 | 16 | 20 | 20 | 30* | 40* | 50* | 60* | 60* | 60* |

| stainless steel | [mm] | 4 | 10 | 15 | 20 | 30* | 40* | 50* | 60* | 60* | 60* |

| aluminium | [mm] | 2 | 6 | 12 | 15 | 30* | 35* | 40* | 50* | 50* | 50* |

| brass | [mm] | 2 | 4 | 6 | 8 | 12 | 15 | 20 | 30* | 30* | 30* |

| copper | [mm] | 1,5 | 4 | 6 | 6 | 10 | 15 | 20 | 25 | 25 | 25* |

Maximum thicknesses of the materials to be processed. The values that are achieved depend on the quality of the material being processed, the quality of the cutting gases, the quality of the service and the NC program and the condition of the wearing parts

* Heavy duty (HD) laser cutter version with CatLine option

| Control | Beckhoff TwinCAT CNC |

| Compressed air | [BAR] | 25-30 |

| Nitrogen pressure | [BAR] | 25-30 |

| Air pressure | [BAR] | 8-10 |

| Laser type | Ytterbium laser fiber | |

| Available laser sources | [kW] | 2-20 |

| Wavelength | [µm] | 1,07 |

| Beam quality | mm x mrad | 3, 4-4,0 |

| Frequency | [kHz] | 5 |